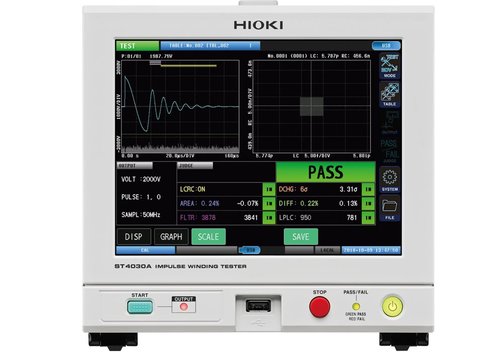

HIOKI ST4030A Impulse Winding Tester

Benefits of the ST4030A Surge or Impulse Winding Tester

- Inspection of rotor in assembled condition.

- 200 MHz high-speed sampling with 12 bit high-precision waveform detection.

- Identify single-fault turns via quantification of response waveforms into LC and RC values.

HIOKI ST4030A Impulse Winding Tester

The HIOKI ST4030A is an instrument for the diagnosis of the insulation quality and deterioration of rotor windings while in assembled state via response waveform quantification. The ST9000 is a factory installed discharge detection upgrade: Detect pseudo-shorts with a high degree of precision.

The ST4030A detects the existence of layer shorts between coil windings, defects that are found in motor inductors. By using a master waveform taken from a reference coil after applying an impulse voltage, and comparing it to the measured waveform across a specific interval of the coil under test, the resulting area difference can help determine pass or fail easily and accurately. In addition, quantification of response waveforms, a new method developed by HIOKI, lets you detect even single-turn faults by using a pass/fail distribution plot.

- Impulse winding tester for inspection of rotor in assembled condition.

- Combines the functions of a resistance meter and insulation-withstand testing required for electric motor winding manufacturers.

- One turn short detection, detect partial discharge with high accuracy, detect insulation failure between motor windings.

- Detect waveforms with high precision (200 MHz high speed sampling, high 12-bit resolution).

- New approach: Quantification of response waveforms into LC and RC values (vs. conventional approach: Area comparison based on waveforms).

- Testable inductance range 10 µH...100 mH.

- 8.4"/21.3 cm SVGA color TFT LCD touch screen.

- Interfaces: LAN, USB, optional: GPIB, RS232C.

- Applications: Test rotor assembly status. Detect single-turn faults. Improve quality by capturing accumulated turn fault data as feedback for upstream processes.

Model Overview

| Model | ST4030A |

| Measurement items | Quantification (LC value, RC value) of the response waveform obtained when impulse voltage is applied, pass/fail judgment. Waveform judgment using AREA value, Flutter, Laplacian etc. Equipped with dielectric breakdown voltage test function. |

| Applied voltage | 100...4200 V (setting resolution: 10 V steps); maximum applied energy: approx. 88 mJ |

| Testable inductance range | 10 µH...100 mH |

| Sampling | 200 / 100 /50 / 20 / 10 MHz, resolution: 12 bit, number of data: 1001...800 points (1000 point steps) |

| Voltage detection accuracy | (DC accuracy) ±5% of setting, (AC band) 100 kHz: ±1 dB |

| Determination method | LC/RC value judgment, waveform judgment, discharge judgment (when incorporating the ST9000) |

| Number of test condition tables | 255 (test condition setting, judgment condition setting, master waveform) |

| Test time | About 60 ms (3000 V, 1 pulse, reference value at decision OFF) |

| Display | 8.4"/21.3 cm SVGA color TFT liquid crystal (800x600 dots), touch panel |

| Interfaces | Standard: EXT I/O, USB host and device, LAN; optional: RS232C (Z3001), GPIB (Z3000) |

| Power supply | 100...240 VAC, 50/60 Hz, max. 80 VA |

| Dimensions (mm) | 215 x 200 x 348; 6.7 kg |

Included: HIOKI ST 4030A, power cord, instruction manual, application CD, usage notes.

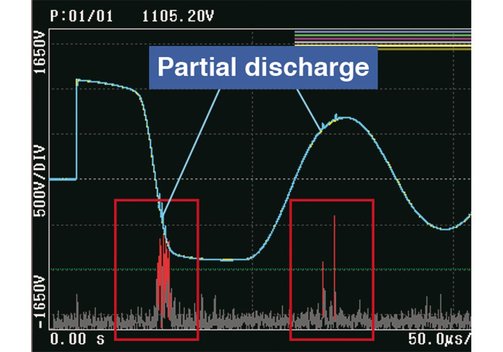

Discharge Detection Upgrade ST9000

The upgrade ST9000 is an optional function for the ST4030A. It allows to detect microscopic partial discharges obscured by noise and to detect pseudo-shorts with high accuracy.

- Option additional function for ST4030A (factory installed option - please specify at the time of order).

- Detection enhancements to spot discharge that is buried in noise to determine defective insulation (pseudo-shorts).

- HIOKI original filter: Noise components within the high frequency components appearing within the entire response waveform are removed to extract only the partial discharge component in order to make a pass/fail determination.

- No peripheral equipment (antenna for discharge detection etc.) required to easily detect discharge.

Information on product safety:

Manufacturer:

HIOKI E.E. Corporation, 81 Koizumi Ueda, Nagano 386-1192/JPN

www.hioki.com

(EU branch Germany)